Introduction

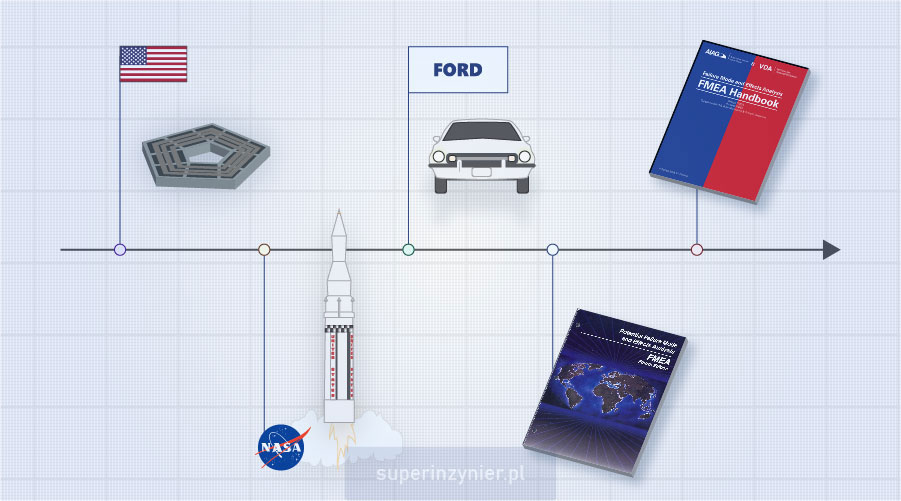

FMEA risk analysis as a documented procedure was developed in the late 1940s. Initially, FMECA/FMEA was utilized in the military industry, specifically in aviation, followed by the space industry, where NASA adopted it. Later, in the 1970s, it was introduced to the automotive industry by Ford. Today, FMEA is a widely employed risk analysis method in various industries, including but not limited to those mentioned earlier.

Various standards

Over the years, several manuals have been developed to describe how to implement FMEA risk analysis. In the aerospace industry, these include NASA/ESA standards, ARP-5580, SAE-13004, ISO-16602, ISO-60812 and others. In the automotive industry, there are manuals issued by associations such as AIAG, VDA, SAE, ANFIA. In addition, some OEMs have issued their own manuals, such as: Ford, JLR, Renault, PSA.

Many different handbooks signify many different methods of conducting FMEA analysis. These differences have caused a series of misunderstandings and difficulties during FMEA analysis. It was particularly challenging in the automotive industry, but actions are currently being taken to reduce these discrepancies. We will see what the results will be.

History of FMEA

Below are key dates and standards related to the development of the FMEA method. Of course, this is a somewhat subjective selection ;)

- 1949. The U.S. Department of Defense developed the MIL-P-1629 procedure[1,2]. Based on this document, the MIL-STD-1629 (SHIPS) standard was created in 1974, and updated in 1980 as MIL-STD-1629A[2,3]. Ultimately, the standard was canceled in 1998[4].

- 1963+. In the 1960s, NASA applied FMECA/FMEA analysis to the Apollo project[5], followed by the Viking, Voyager, Magellan, Galileo, and Skylab programs[6].

- 1970+. In the mid-1970s, Ford Motor Corporation introduced the FMEA methodology to the automotive industry, as a consequence of issues with the Pinto car. Ford developed its own FMEA handbook, which included CFMEA (product concept), DFMEA (product design), and PFMEA (production process) analyses. This FMEA handbook is still evolving. In my opinion, it is a very well-developed and valuable document.

- 1993. The AIAG organization, founded by the "Big Three from Detroit" - GM, Ford, and Chrysler, published the FMEA Reference Manual for the QS9000 system. This manual includes principles for developing FMEA analysis for product design (D-FMEA) and for its manufacturing process (P-FMEA). The FMEA Reference Manual was one of the five documents developed at that time: APQP, FMEA, SPC, MSA, PPAP. These reference manuals are now referred to as "Core Tools" in the automotive industry.

- 1994. The American organization SAE (SAE International, originally the Society of Automotive Engineers) released the SAE-J1739 manual, which was conceptually consistent with AIAG FMEA.

- 1995. The second edition of the AIAG FMEA Reference Manual.

- 1996. The German organization VDA released Volume VDA 4. In the second part of this volume, the FMEA method for the system, FMEA design, and FMEA process were described. This was a concept based on a network of functions and error networks, somewhat reminiscent of the FTA method.

- 2001. The third edition of the AIAG FMEA Reference Manual.

- 2006. VDA introduced an update to risk assessment in VDA 4. The second edition was created, defined as FMEA product and process. In 2009, there was a "reprint", so some opinions state that the second edition was in 2009, but formally, it was the 2006 edition.

- 2008. AIAG released the fourth version of the FMEA Reference Manual, often referred to as AIAG FMEA-4. This standard is the most popular FMEA method worldwide, both in the automotive industry and in many other industrial branches. Car manufacturers (OEM) often accepted analyses based on AIAG FMEA-4, even though they had their own FMEA handbooks. This information was sometimes also included in their CSR (Corporate Social Responsibility) documents.

- 2009. SAE updated SAE-J1739 to ensure compliance with AIAG FMEA edition 4.

- 2012. VDA updated FMEA in VDA 4. The document was updated in terms of graphics and examples. Graphic unification aimed to eliminate suggestions for using specific software for FMEA analysis. Finally, in 2021, FMEA was removed from VDA 4, and a reference to the external AIAG-VDA FMEA manual was added[7].

- 2017. SAE-13004 was created, a standard developed by SAE for the aviation industry, focusing only on the production process (P-FMEA). In terms of content, this method is almost identical to AIAG FMEA-4.

- 2019. AIAG and VDA released a joint AIAG-VDA FMEA manual. This document combined certain aspects of the AIAG FMEA-4 method with the concept of structure and function/error networks derived from the VDA method. Unified tables for S, O, D indicators were developed. The Risk Priority Number (RPN) was replaced by a slightly better thought-out risk assessment called AP. Automotive part manufacturers were obligated to implement the AIAG-VDA approach for new projects, taking into account specific customer requirements (CSR). For existing projects, the previous approach could be applied.

- 2021. SAE updated the SAE-J1739 standard, introducing S, O, D ranking tables and a risk level assessment based on AP consistent with AIAG-VDA FMEA. Use of RPN was left as an option. In this way, this standard essentially applied the same risk assessment principles as AIAG-VDA FMEA but allows to use a simple and user-friendly FMEA form consistent with AIAG FMEA-4.

Summary

FMEA analysis originated in the military and aerospace industries in the mid-20th century. It was gradually adopted by the automotive industry and is now being applied in many other sectors. Several established manuals and standards on FMEA are now available.

When using FMEA, practitioners, trainers, and facilitators will take different approaches. One reason for these differences is the large number of manuals and standards, which sometimes describe significantly different principles for conducting the analysis. The selection of an appropriate manual or standard depends mainly on the industry in which we operate and, most importantly, on our customers' expectations.

In summary, when conducting an FMEA analysis, it is of utmost importance to clearly establish the principles by which the analysis will be conducted. This is a key responsibility that ensures the quality and reliability of the analysis. It is important to determine which manual or standard will be used, and to precisely identify any differences from the chosen standard.

References

- C. J. Middleton, "Risk Assessment Planning for Airborne Systems: An Information Assurance FMECA Methodology," Air Force Inst. of Technology, Wright-Patterson AFB, OH, USA, June 2012.

- R. A. Harpster, What Is a Design FMEA?; Harpco Systems.

- MIL-STD-1629, "Procedures for Performing a Failure Mode Effects and Criticality Analysis," U.S. DoD, 1980.

- MIL-STD-1629 NOTICE-3, "Notice of cancellation" U.S. DoD, 1998

- NASA, "RA-006-013-1A. Apollo Program. Procedure for Failure Mode, Effects, and Criticality Analysis (FMECA)," 1966.

- NASA, "PD-AD-1307. Failure Modes, Effects, and Criticality Analysis (FMECA)."

- VDA-QMC, "VDA 4. Quality Assurance in the Process Landscape. Section 2. Risk Analysis," 3rd ed., 2021.