Introduction

In the previous article about the 5W2H technique, I mentioned the possibility of expanding it with an additional "dimension" for problem description called Is / Is Not. This extension enables a more detailed analysis of the situation and better preparation for identifying root causes.

Why is this important?

A precise problem description using the "Is / Is Not" technique allows for:

- Faster analysis - narrowing down the list of potential causes to the more probable ones.

- Elimination of misunderstandings - sometimes the problem arises from communication errors, misinterpretation of data, or the issue being attributed to the wrong entity (e.g., another supplier).

- Accurate problem description (2D) in 8D - this is the recommended approach for describing problems (2D) in methodologies such as 8D and Global 8D (G8D).

In my professional practice, I have encountered situations where using 5W2H and "Is/Is Not" revealed that the problem either did not exist or pertained to a completely different entity (supplier). Such misunderstandings can be time-consuming and costly. Hence, my recommendation: use the 5W2H technique combined with the Is / Is Not method, especially for more complex problems.

Is / Is Not - The Concept

"Is / Is Not" is a simple yet highly effective method for supporting problem description. It focuses on analyzing two key aspects:

- What is (IS) - elements actually present in the analyzed situation.

- What is not (IS NOT) - elements that could have occurred but did not.

Imagine a situation where a customer complaint is being analyzed. Two example questions might look like this:

- Who?

- IS: Customer X reports an issue with Product Y.

- IS NOT: Other customers (i.e., we have not received complaints from other users of Product Y).

- How?

- IS: The problem occurs during cold engine startup.

- IS NOT: The problem does not occur during warm engine startup.

This approach allows for a better understanding of various aspects of the issue. At the initial stage of analysis, it helps to rule out some potential causes that do not logically align with the descriptions under IS and IS NOT categories.

Note! - The opposite is not true, as correlation does not imply causation, and this error is easy to make when solely relying on the problem description.

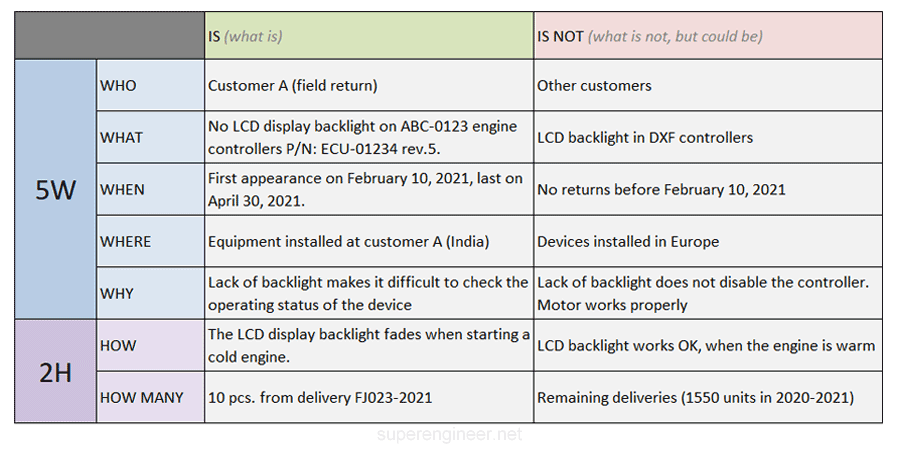

Is / Is Not + 5W2H - Example

Is / Is Not - Various Variations

Combining the "Is / Is Not" technique with "W" questions (Who, What, When, Where, Why) and "H" questions (How, How Many) creates a versatile framework for problem description. In business practice, various combinations of "W", "H", and other aspects are used together with "Is / Is Not". For example:

- 5W2H: Who, What, Where, When, Why, How, How Many.

- 5W1H: Who, What, Where, When, Why, How.

- Global 8D: What, Where, When, How Big.[1]

- VDA 8D: What, Where, When, Scope.[2]

- AIAG CQI-20: What, Where, When, How Big.[3]

- Kepner-Tregoe (KT): What, Where, When, Extent.[4]

Modifications to "W" and "H" questions depending on the context allow the technique to be adapted to the specific requirements of a given industry or project. This makes the "Is / Is Not" method easier to apply in particular situations.

Conclusion

The "Is / Is Not" technique combined with "5W2H" is an excellent tool for supporting precise problem definition. Thanks to this:

- You accelerate the process of problem analysis and elimination.

- You reduce the risk of addressing non-existent issues ;-)

- You enhance the effectiveness of corrective actions.

I encourage you to use this technique as part of the 8D or G8D methodology, especially when solving more challenging quality issues.

References

- Ford Motor Corp., Global 8D Reference Guide, 2018.

- Verband der Automobilindustrie e. V. (VDA), 8D - Problem Solving in 8 Disciplines, 1st ed., 2018.

- AIAG, CQI-20 Effective Problem Solving, 2nd ed., 2018.

- https://kepner-tregoe.com/