Introduction

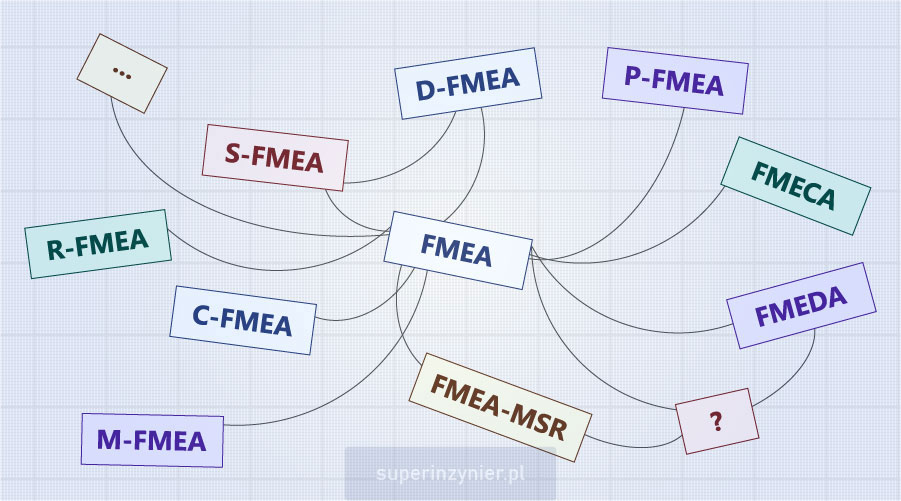

While browsing various websites on the Internet (what irony...), you may come across terms like FMEA, FMECA, and FMEDA. Going further, a "regular" FMEA analysis is divided into various variants: S-FMEA, D-FMEA, P-FMEA, FMEA-MSR, M-FMEA, R-FMEA, etc. It's a bit complicated...

The aim of this article is to outline what these acronyms mean and the application of each type of analysis. It's also worth reading a short article, The FMEA History, which helps in better understanding the genesis of FMEA and the currently applied standards.

FMEA, FMECA, FMEDA

FMEA

FMEA stands for "Failure Mode and Effects Analysis." It is the most common type and widely popular form of risk analysis. The product or its manufacturing process is divided into smaller elements, specifying functions/requirements, defects, followed by consequences and causes. Then, so called "prevention" and "detection" methods are estimated. Finally, risk is assessed according to specified indicators. FMEA is a qualitative analysis (i.e., we don't use "hard" component failure rates). We rely on simple tables for S, O, and D indicators.

FMECA

FMECA stands for "Failure Mode, Effects, and Criticality Analysis". It is a risk analysis where a similar analysis to a regular FMEA is performed. Then, the level of criticality is determined based on either a "qualitative" (easier) or "quantitative" (more challenging but more reliable) approach.

FMEDA

FMEDA is an acronym for "Failure Mode, Effects, and Diagnostics Analysis". This method is mainly applicable in designing devices that must meet safety requirements, typically according to IEC 61508 (SIL) or ISO-26262 (ASIL). Similar to FMECA, it identifies individual components, types of defects, and consequences. Then, it determines the failure rate, and the diagnostic coverage, etc. FMEDA is, of course, a quantitative analysis based on appropriate component reliability data.

Types of FMEA

A "regular" FMEA has many variants. Depending on the application, you may encounter terms like D-FMEA, P-FMEA, S-FMEA, C-FMEA, etc. What do these acronyms mean?

C-FMEA

C-FMEA (Concept FMEA) is basically a simplified analysis of D-FMEA. It can be applied at the initial stage of creating a new product when considering several different concepts. We don't focus on construction details, which don't exist yet. Thanks to C-FMEA, you can choose a less risky, optimal solution.

S-FMEA

S-FMEA (System FMEA) is essentially D-FMEA at the level of the entire product (or subsystem), where interactions between the product and external systems, the environment, the user, and between internal subsystems are analyzed. System FMEA makes sense for complex products.

D-FMEA

D-FMEA (Design FMEA) is a risk analysis evaluating the product's design, where a specific design with defined components and product characteristics is assessed. During DFMEA, causes related to these characteristics that may lead to the incorrect fulfillment of a given function are identified.

FMEA-MSR

FMEA-MSR (Monitoring and System Response) is a complement to typical D-FMEA, focusing on aspects related to the product's operation. Failure or incorrect use affecting safety or legal requirements is considered. This method evaluates how a hazardous situation can be detected (Monitoring) and whether an appropriate response (System Response) can be implemented to reduce the risk. For example, safely shutting down the device, entering emergency mode, warning the user, etc.

M-FMEA

M-FMEA (Machine FMEA) is a method related to machine design. It is essentially a construction FMEA with slight modifications compared to typical D-FMEA. I recommend this method to machine, mold, tool, and functional testing system designers (e.g., functional testers).

P-FMEA

P-FMEA (Process FMEA) is an analysis used to assess risk in the production process. The team conducting PFMEA tries to identify possible product defects caused by factors on the production process side (human work, machines, environment, additional material, etc.).

L-FMEA

L-FMEA (Logistic FMEA) is essentially P-FMEA for logistic processes (transport, storage, shipping, etc.). I haven't heard of any official L-FMEA handbook. Some organizations separate logistic processes in the plant, and their P-FMEA analysis is referred to as L-FMEA. It's worth noting that formally, P-FMEA should cover the entire "from dock to dock in the plant" process, so practically, most logistic processes fall under P-FMEA.

R-FMEA

R-FMEA (Reverse FMEA) is a review and update of an existing P-FMEA based on a physical review of the process directly on the line (at the machine or workstation). The goal is to improve P-FMEA by correcting errors, adding new types of defects, adding new causes, verifying detection methods, etc. This has become a "trendy" topic in the automotive industry due to the addition of R-FMEA to some CSRs (Customer Specyfic Requirements).

Others

In addition to the mentioned types of FMEA analyses, various other acronyms can be encountered, such as SW-FMEA (software FMEA), Interface-FMEA, Service-FMEA, etc. Generally, these are just FMEA projects or FMEA process analyses with minor changes. You may also come across an analysis called DRBFM (Design Review Based on Failure Mode), developed at Toyota Motor Corporation.

Summary

Various methods can serve as the basis for risk analysis, depending on the specifics of a particular industry, customer requirements, and the function the analysis aims to fulfill. An engineer benefits from being aware of different standards and acronyms in use, as it aids in selecting the appropriate FMEA method for a given application.