IPC: Requirements flowdown

Let's say a Manufacturer assembles a product consisting of:

- A large motherboard, which it manufactures in its own plant

- A small "daughter" board outsourced to a subcontractor

- Wiring harness, ordered from a local supplier

- LCD display, purchased from a distributor. The LCD is made in China

During final assembly, the manufacturer solders an additional wire to the LCD control board.

The final (end) product in the documentation has a class 3. What to do with the requirements for suppliers, since we have no influence on the class of the LCD (it is, after all, a "catalog" product)? Should our local wire harness supplier know what IPC/WHMA-A-620 is?

These questions are answered by the requirements flowdown given in standards IPC-A-610 Rev.H par. 1.9, J-STD-001 Rev.H par. 1.9, IPC/WHMA-A-620E par. 1.9. These are rules that shall be followed to ensure that quality requirements are correctly communicated "downstream" in product documentation and in orders to suppliers.

Before discussing the principles of requirements flowdown in more detail, we should first familiarize ourselves with the concept of COTS.

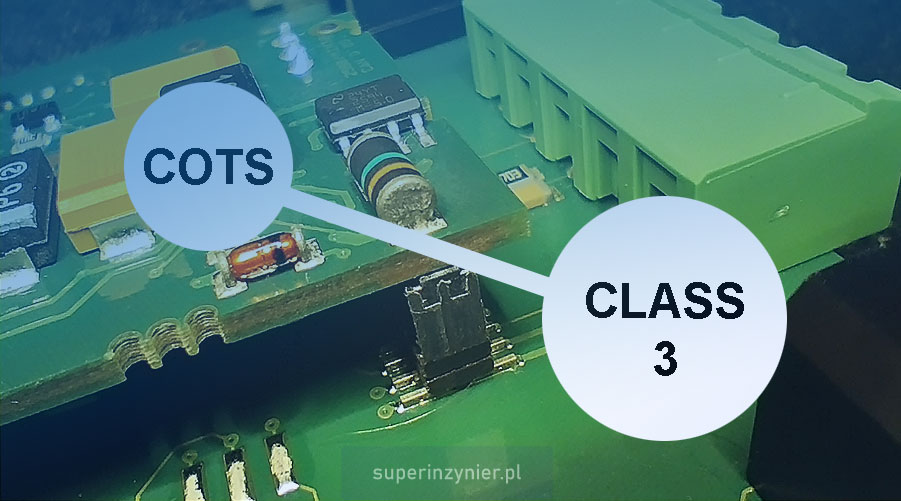

COTS

COTS stands for "Commercial Of The Shelf" and refers to software, components, subassemblies, electronic modules that are publicly available as "catalog products". When we purchase these products, we have no control over the class of their workmanship. We assume that they are made to their own specifications, and we cannot impose our own requirements.

Rules of requirements flowdown

If a product has a specific class in the documentation or order, transfer these requirements "downstream" to the individual subassemblies that will be manufactured specifically for that product.

Flowdown means that the manufacturer of this product should include class requirements in its drawings, work instructions and orders to suppliers.

The requirement to communicate product class requirements does not apply to COTS modules/subassemblies. If the contract requires otherwise, then the contract provisions apply.

If the situation is unclear and it is not known if a component is to be manufactured according to the class of finished product or not, it is the responsibility of the Manufacturer to clarify this issue with the User (customer).

Assembly of COTS to the product

Connections/assembly between the COTS component (e.g., LCD display) and the rest of the product (e.g., motherboard) should meet the requirements of the class.

If the Manufacturer makes products according to a given class and at the same time also make a COTS subassembly, the soldering of the entire product should meet the requirements of the class (including the entire COTS subassembly).

COTS modification

If the documentation requires modifications to COTS (e.g., adding some components or wires), the changes made should meet the requirements of IPC standards of the final product class.

Summary

Proper requirements flow is a very important aspect, which if not met can be very costly, both for the Manufacturer and the User (customer). It is necessary to make sure that the requirements have been correctly transferred to the documentation of subassemblies ordered for a given project, i.e. documentation for PCB order, "daughter" board assembly order, wiring harness order, etc. Particular attention should be paid to cases where we are transferring production from another plant and are already using pre-selected suppliers or suppliers imposed by the User (customer). It may turn out that the suppliers did not have the correctly communicated requirements. Who will then bear the costs?