Introduction

Electronic devices are becoming increasingly integrated into daily life, with all indications that their influence on society will continue to grow. The surge in demand for electronics has led to numerous companies now engaged in the manufacturing, installation, and ongoing maintenance of these devices.

The industry's customers and suppliers span the USA, Europe, and Asia. So, how can we set consistent and clear criteria for visually assessing electronics assembly quality across such a global landscape?

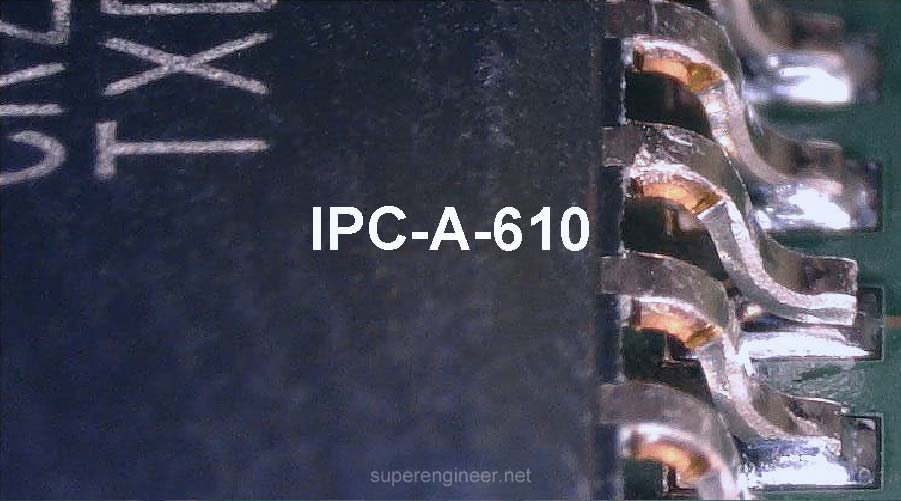

To meet these needs, the IPC-A-610 Acceptability of Electronic Assemblies standard was developed, outlining quality requirements for the visual inspection of electronic assemblies.

This article introduces IPC-A-610, covering its key aspects and presenting the main chapters of the standard.

Let's dive in!

The History of IPC-A-610

The IPC-A-610 standard was created by IPC in 1983 and has been regularly updated. As of 2024, the latest version of the standard is version "J," released in March 2024 and formally titled IPC-A-610J.

Interesting fact: there is no version "I" of the standard. IPC released version "H" in 2020, followed by version "J" in 2024. The letter "I" was skipped to avoid confusion, as it could resemble the number "1" or lowercase "L," potentially leading to misunderstandings like interpreting "IPC-A-610I" as "IPC-A-6101" or "IPC-A-610L."

You can easily check the revision history of any IPC standard and find the latest version on the IPC website under the "Document Revision Table" section.[1]

Scope of IPC-A-610

The IPC standard defines visual inspection criteria for electronic assemblies.

Electronic assemblies refer to PCBs with soldered components. Sometimes terms like electronic modules or packets are also used, and the acronym PCBA (Printed Circuit Board Assembly) is common.

Inspection criteria include conditions (acceptable, process indicator, defect), which cover various observations that may arise during the inspection of assembled electronics. Notably, in version "H" from 2020, a significant change was made—the target condition was removed.

IPC-A-610 does not cover the following aspects:

- It does not include cross-section evaluation criteria.

- It does not authorize rework or repair. It only specifies how to evaluate their quality. Customer approval for repair is a separate matter. Learn more in the article: Rework or Repair.

- It does not define requirements for assembly processes. The standard does not specify materials, such as lead-based solder, lead-free solder, flux, or SMT solder paste. It also does not define SMT reflow profiles or wave soldering profiles.

IPC-A-610 and Other Standards

IPC-A-610 is one of many standards for electronic assemblies. The second chapter of this document references numerous related standards from IPC, JEDEC, and IEC.

IPC-A-610 may be used when the following conditions are met:

- The PCB design adheres to established standards, like the IPC-2220 series or similar.

- The PCB is manufactured according to standards, such as the IPC-6010 series.

- The PCB meets the visual requirements outlined in IPC-A-600.

- Soldering follows standard processes using typical materials.

For unusual PCB designs, non-standard manufacturing processes, or specific soldering methods, custom criteria should be developed.[2]

IPC-A-610 Inspection Rules

IPC-A-610 provides key principles for inspecting assembled PCBs. Here are some of the most important ones, though the full requirements are detailed in Chapter 1 of the standard.

- The English version takes precedence. Translation errors in IPC standards can occur. When discrepancies exist between the English and translated versions, the English text is authoritative.

- The product class is determined by the user. The inspector does not assign the IPC product class.

- Follow order of precedence. IPC-A-610 clarifies how to handle discrepancies between the standard and customer requirements, using rules known as order of precedence and requirements flowdown.

- Ensure personnel proficiency. The standard requires that instructors, operators, and quality control personnel demonstrate proficiency in their jobs. Companies should maintain records verifying personnel qualifications, including education, experience, training, and testing to the standard. If qualifications are lacking, supervision and on-the-job training should be provided until proficiency is achieved.

- Text over illustrations. Always prioritize the text of the requirement over illustrations, as images can sometimes exaggerate or mislead.

- Use appropriate magnification tools. Depending on the size of the solder land inspected, use a proper magnifier or microscope. If additional verification is needed, use higher magnification as specified in tables 1-2, 1-3, and 1-4 in IPC-A-610J.

- Maintain adequate lighting. Ensure surface illumination of at least 1000 lux and a light color temperature of 3000-5000 °K during inspections.

Main Chapters of IPC-A-610

The "J" version of IPC-A-610 contains the following chapters:[2]

- General

- Applicable Documents

- Handling Electronic Assemblies

- Hardware

- Soldering

- Terminal Connections

- Through-Hole Technology

- Surface Mount Assemblies

- Component Damage

- Printed Boards and Assemblies

- Discrete Wiring

- High Voltage

- Jumper Wires

Appendix A: Protecting the Assembly - ESD and Other Handling Considerations

Summary

IPC-A-610 is a globally recognized standard for visually inspecting assembled electronics. Developed by IPC, it provides consistent quality requirements and inspection criteria that can be applied across the global supply chain.

IPC-A-610 covers various aspects of assembled electronics, including soldering anomalies (e.g., nonwetting and dewetting), mechanical assembly, wiring, THT, SMT, component damage, and PCB appearance issues. It allows suppliers and customers to determine if a product meets established quality standards.

Regular updates ensure that IPC-A-610 reflects the latest quality requirements. It's a well-crafted, practical document that prioritizes real product quality and reliability over mere visual aspects - something I truly value.

I highly recommend that every electronics engineer and industry professional get familiar with the IPC-A-610.

References

- https://www.ipc.org/ipc-document-revision-table

- "IPC-A-610: Acceptability of Electronic Assemblies," Rev. J, IPC International Inc. USA, 2024.