IPC: Order of precedence

The manufacturer should build products according to the specified requirements. These requirements may be contained in various documents such as technical documentation, agreement (contract), requirements of various standards, concessions (derogations) and other arrangements. How should one proceed if these requirements sometimes contradict each other?

Some IPC standards such as IPC-A-600, J-STD-001, IPC-A-610, IPC/WHMA-A-620 define order of precedence to prevent misunderstandings arising as a result of these very differences.

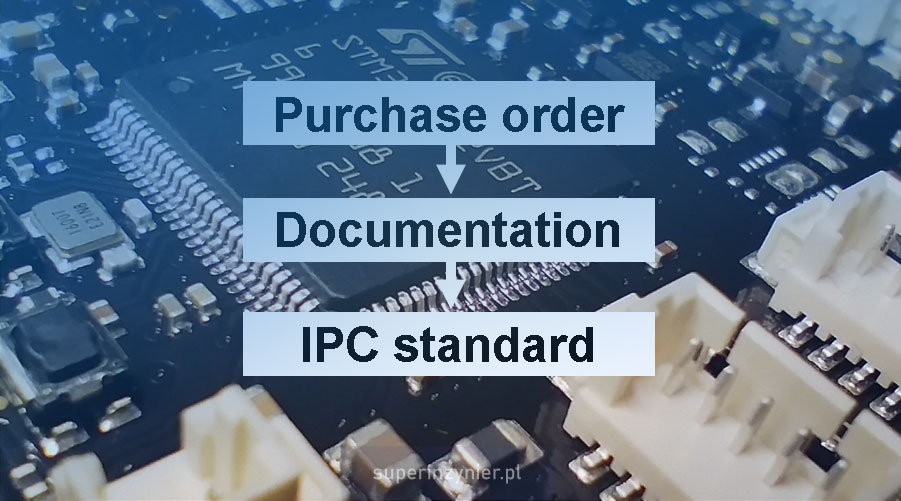

Simplifying somewhat, regardless of the type of IPC standard, the order of precedence from the most important criteria to the least important is as follows:

- Customer purchase order, agreement, contract

- Technical specifications (product drawings, schematics, BoM)

- IPC standard. If more than one standard is listed, specify the order of precedence between them.

This means that the most important is the purchase order, the contract/agreement (1). Then the technical specification of the product applies (2), and only in "third place" are the IPC standards (3). Thus, it can be deduced that IPC standards are not the most important, and if the customer requires the assembly of a product that does not comply with these standards, then that is the way it is supposed to be - "the customer is always right."

The following are the order of precedence for selected IPC standards, put in my own words (these are not verbatim quotes from individual documents).

IPC-A-600

Order of precedence in the IPC-A-600:

- Purchase order and agreed exceptions to documentation

- Documentation related to the order (drawings, gerberas, stack-up, etc.).

- Other documents specified by the customer

- The end item performance specyfication like IPC-6010 standard (series), if invoked by the customer

- IPC-A-600. PCBs should be of uniform quality and should meet the requirements of IPC-6010 (series)

IPC-A-610

Order of precedence in the IPC-A-610:

- Procurement as agreed and documented between Manufacturer and User

- Master drawing or assembly drawings reflecting the User's requirements

- IPC-A-610 if cited by the user or included in the contract

If documents other than IPC-A-610 are cited, their order of precedence should be defined in the procurement documentation.

IPC/WHMA-A-620

Order of precedence in the IPC/WHMA-A-620:

- Procurement as agreed between the Manufacturer and the User

- Engineering documentation reflecting the User's requirements

- IPC/WHMA-A-620 if cited by the User or included in the contract

If IPC/WHMA-A-620 is cited as the only standard, then the requirements of IPC-A-610 and J-STD-001 do not apply.

If IPC/WHMA-A-620 is cited along with IPC-A-610 or J-STD-001, the acceptance criteria should be specified in the contract or otherwise agreed with the User. The User may also specify alternative acceptance criteria.

What about the J-STD-001?

The IPC-A-600, IPC-A-610, IPC/WHMA-A-620 standards are for product inspection and do not specify requirements for assembly processes. In contrast, the J-STD-001 standard specifies a number of requirements related to materials and process control, and thus has a different meaning for the manufacturer's business relationship with the customer.

The order of precedence in J-STD-001 can be summarized as follows:

- Contract between the Manufacturer and the User

- Engineering documentation approved by the User

- Requirements of J-STD-001

- Requirements of applicable documents cited in J-STD-001

If J-STD-001 is cited in the contract, IPC-A-610 requirements do not apply unless additionally cited. If IPC-A-610 or other standards are cited in the contract, the priority criteria must be established in the contract.

The IPC-A-610 standard can also be used as an add-on to J-STD-001 containing a visual representation of the requirements of J-STD-001. Of course, care should be taken to ensure that both standards are in the same version to minimize any differences.

Summary

Order of precedence is an important aspect related to the determination of requirements between the User (customer) and the Manufacturer. This is especially important when a number of different standards and industry-specific requirements are invoked.

From the User's point of view, it is worth considering the inclusion of J-STD-001 as part of the contract, which obliges the Manufacturer to use appropriate materials and process control methods. This approach should minimize possible variability in the products supplied.

If the customer specifies an assembly that does not meet the requirements of the IPC standards, the customer's specifications should be used. In such a situation, I recommend contacting the customer and explaining the differences. In my practice, there have been several cases where the customer did not know the requirements of the IPC standards and changed their own specifications after consultation.