Introduction

Soldering is a method of joining metal pieces with the help of a filler material, called a solder alloy, whose melting point is lower than the melting point of the pieces being joined.

In the soldering process, the solder alloy is heated to a temperature at which it melts and fuses the soldered surfaces of the components. Bonding the molten alloy to the component material involves mixing the solder particles with particles of the component's base material. It forms a layer referred to as an intermetallic layer. The solder alloy then solidifies during cooling, providing a mechanical and electrical connection between the components.

The soldering process should be carried out in accordance with the established time temperature profile to ensure reproducibility and high quality of the connections.

When soldering, a chemical called flux is used, which greatly facilitates the proper bonding of component surfaces to the solder alloy.

The parts to be joined should have adequate solderability at the soldering surface. These surfaces should be free of contamination (oil, grease, fat, etc.) and free of excessive moisture.

Depending on the melting point of the alloy used, we can refer to a given type of soldering as soft soldering or as brazing.

Soft soldering

Soft soldering uses solder alloys where their melting point is less than 450C. Solder alloys typically include tin-silver-copper (SnAgCu), tin-copper-nickel-germanium (Sn100C), tin-lead (SnPb), low-temperature bismuth-tin alloy (BiSn) and a number of others.

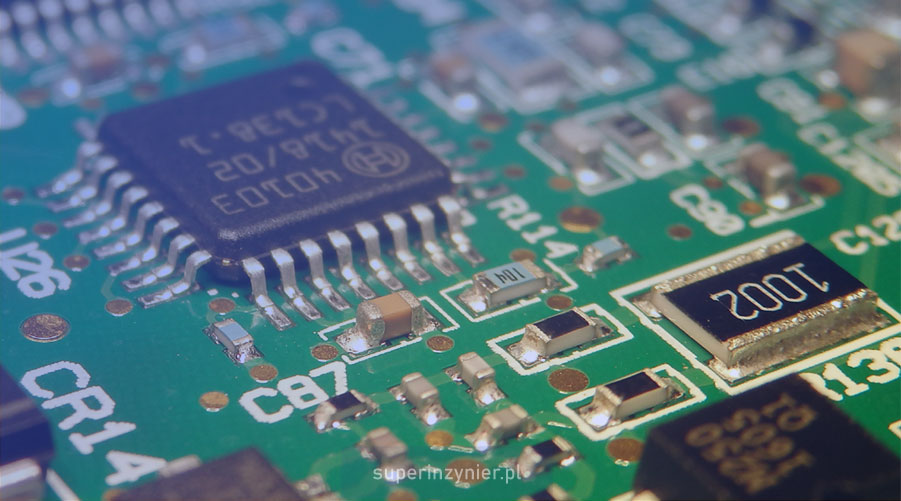

This type of soldering is used, among other things, to assemble electronic components on PCBs, tin wires, solder wires or cables, solder copper pipes, and make various thin-walled containers and tanks.

The advantage of soft soldering is the use of relatively low temperatures, which reduces the thermal stress on the parts to be joined. The disadvantage is the lower mechanical strength of the connections compared to brazing.

In the electronics industry, the solder alloys used are classified according to J-STD-006, and the solder pastes typically used in the SMT process are covered in J-STD-005.

More information about lead based solder alloys and lead-free solder alloys.

Brazing

Brazing uses brazing alloys with a melting point above 450C. They are used to join surfaces such as copper, brass, various steels, bronze, etc. Brazing alloys are usually aluminum, silver, nickel, tin, copper and others.

Brazing is used to join various components where soft soldering cannot be used due to low mechanical strength.

Flux

Flux is a chemical that facilitates the soldering process. Its main role is to remove metal oxides from soldered surfaces. There are many methods of flux application. It can be applied by dipping, spraying, foaming, or it can be applied with the solder alloy in the form of so-called solder paste or inside a solder wire.

Flux will perform its function properly if it is applied correctly, in the correct amount and heated according to the manufacturer's recommendations. Depending on the type of flux and the final cleanliness requirements of the product, flux residues after the soldering process will be removed (washed off) or left behind.

The electronics industry uses fluxes that have been properly classified based on the J-STD-004 standard in terms of composition, activity level and amount of halides. Fluxes are also divided into those requiring cleaning (Clean) and those not requiring cleaning (No-clean).

Active flux residues can reduce the surface resistance on PCBs and facilitate electrochemical migration. The result will be visible dendrites.

Solderability

The surface of soldered components should have a sufficiently high solderability. This characteristic of the soldered surface is related to the so-called wettability (Wetting), i.e. the ability to cover the soldered surfaces with an even, continuous layer of alloy.

We can evaluate wetting based on the appearance of the solidified alloy (solder, joint), the uniformity of coverage of the soldered surfaces and the wetting angle.

In the electronics industry, solderability requirements for component leads are defined in standard J-STD-002 while solderability requirements for PCB lands are defined in standard J-STD-003.

Degradation of surface solderability can lead to the phenomena: nonwetting or dewetting.

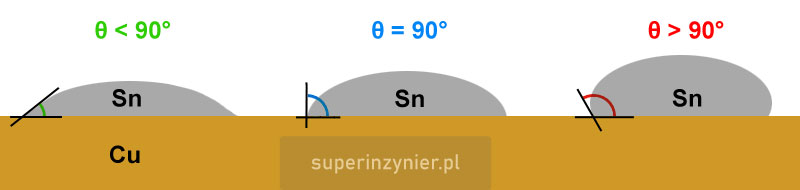

Wetting angle

The wetting angle is the angle formed by the flat surface of the material being soldered and the plane tangent to the surface of the solder bordering that solder surface. In other words, it is the angle at which the edge of the solder alloy makes contact with the solder surface. The smaller the wetting angle, the higher the solderability of the surface (better), the higher the wetting angle, the lower the solderability (worse). If the wetting angle exceeds 90 degrees, it means there is no proper wetting, called nonwetting. Note: there are some exceptions to this 90-degree rule, but this is a topic for another article.

The figure below shows the idea of wetting angle in soldering. Three droplets of tin (Sn) on a copper surface (Cu) have different wetting angles.

Intermetallic layer

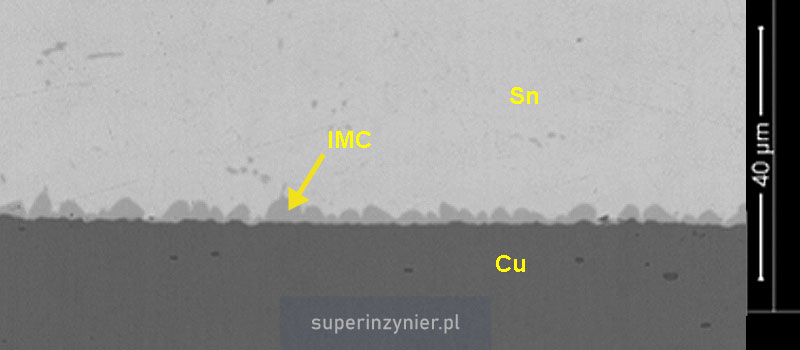

The intermetallic layer is an intermediate phase between the solder alloy and the base material of component leads or printed circuit board (PCB) lands. The layer is formed by the reaction between the liquid solder and the material of the component to be joined. Intermetallic layer plays a crucial role in the soldering process, enabling the materials to bond properly.

The image below, obtained with a scanning electron microscope (SEM), shows a solder joint between copper (Cu) and tin (Sn), where the presence of an intermetallic layer (IMC) is clearly visible:

The intermetallic layer grows with increasing temperature, so repeated soldering of the same joint results in a significant build-up of the intermetallic layer thickness. Unfortunately, this layer is brittle, so excessive thickness can cause a decrease in the strength of the soldered joint. This is one of the reasons why acceptable solder joints should not be unnecessarily remelted.

Correcting acceptable solder joints to make them look perfect is a bad idea. I recommend an article that explains this: IPC-A-610H: Target condition removed.

Time temperature profile

The high quality of solder joints is related to a number of material factors (solderability of the surface, amount of flux, type of alloy) and strongly depends on the temperature and time of soldering.

Depending on the method of soldering used (reflow, wave, manual, etc.), different solutions are used to ensure the right temperature-time profile.

For manual soldering, we rely on ensuring the right equipment, correct temperature settings (soldering iron, blower, heater, etc.) and, most importantly, proper operator training.

For machine soldering, we rely on setting and then monitoring the temperature-time profile - see an article about soldering reflow profile. This profile depends on the requirements set by the material manufacturers (mainly flux) and the requirements of the components to be soldered. The profile includes at least three stages: preheating, contact with liquid solder/solder dissolution, cooling.

More information: reflow soldering profile and wave soldering profile

Copper dissolution

The soldering process causes a copper dissolution effect. To minimize this effect, it is important to understand it and apply proper process controls.

Moisture and SMD components

The reflow soldering process heats components packages above 200°C. If the package of a soldered component contains excess moisture, it can damage to the component.

More on the impact of moisture is presented in the article: MSL of SMD components.

The source of contamination may be improperly performed rework.

Standards

The electronics industry has developed a range of standards related to soldering in electronics. Below are some of the key ones:

- J-STD-001 Requirements for Soldered Electrical and Electronic Assemblies.

- IPC-A-610 Acceptability of Electronic Assemblies.

- IEC 61191-1 Printed Board Assemblies - Part 1: Generic Specification - Requirements for Soldered Electrical and Electronic Assemblies Using Surface Mount and Related Assembly Technologies.

- CQI-17 Special Process: Electronic Assembly Manufacturing - Soldering System Assessment (EAM-SSA).

Summary

Soldering is the process of joining components using a "third material" - the solder alloy. High-quality solder joints require fine-tuning of many aspects simultaneously. Much depends on the quality of the components used (solderability), the materials used, the right tools, staff training and process control methods.

Personnel overseeing soldering processes should understand the impact of these factors, correctly apply and interpret industry standards' requirements, and be aware of process variability.